India’s solar installed capacity reached 20 GW in February 2018. India expanded its solar-generation capacity 8 times from 2,650 MW on 26 May 2014 to over 20 GW as on 31 January 2018.The 20 GW capacity was initially targeted for 2022 but the government achieved the target four years ahead of schedule.

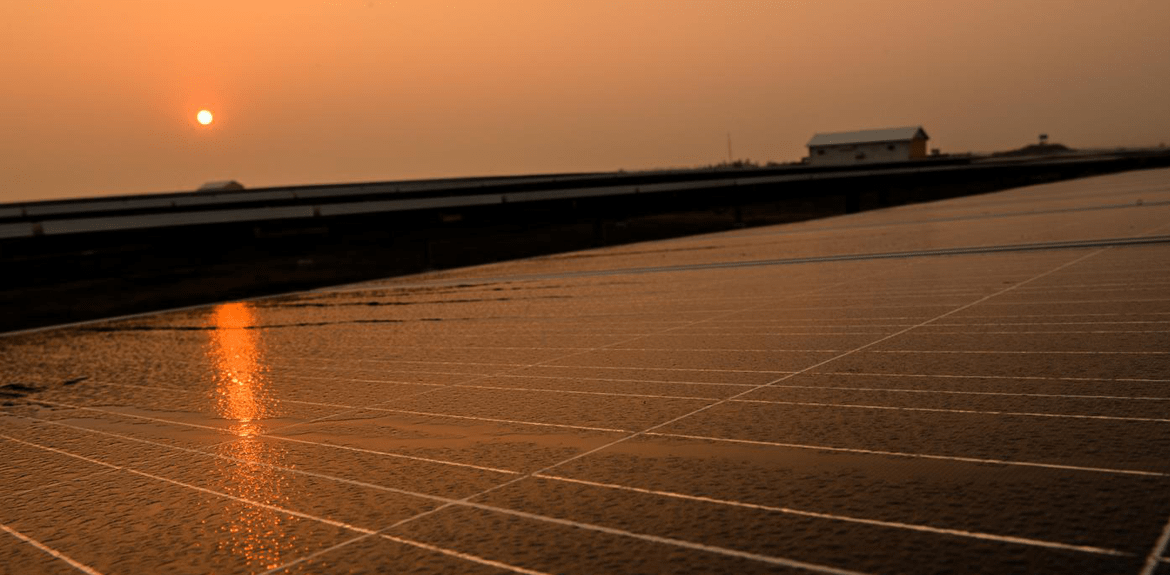

In January 2015 the Indian government expanded its solar plans, targeting US$100 billion in investment and 100 GW of solar capacity (including 40 GW from rooftop solar) by 2022. "With a sweeping commitment to solar power, innovative solutions and energy efficiency initiatives to supply its people with 24x7 electricity by 2030, India is emerging as a front-runner in the global fight against climate change," the World Bank said in a news report published in July 2017. The country added 3 GW of solar capacity in 2015-2016 and over 5 GW in 2016-2017, the highest of any year. Greenko’s 816MWp Ultra Mega Solar Park at Kurnool contributed to this giant leap. Construction of the Plant was started in October 2016 and commissioned on 31st March 2017 – in 166 days, much ahead of the scheduled commissioning date of April 21st, 2017.

Sourcing critical component:

The most critical component- PV modules were sourced from tier-1 suppliers like Trina Solar, Risen, GCL and REC. The requirement of 2.45 Mn modules over a span of 3 months was a daunting challenge to meet -we blocked the entire capacities of these manufacturers. As we were racing against time, we stationed our quality teams at the manufacturer’s factory for 4 months so that the quality fully assured. Multiple third-party QA labs were also plugged into service to ensure that no defectives crept into this prestigious Plant. The inverters were sourced, after careful evaluation of multiple factors impacting the fulfilment of PPA, from internationally renowned supplier SMA of Germany. The HT panels were sourced from ABB & Siemens.

Logistics challenge:

The inverters were air shipped through Bangalore airport to crash the critical path to the required timelines. More than 4,000 people were mobilised by contractors and a team of 200 Greenko employees was stationed at the site for over 4 months. To accommodate the heavy traffic in the short span of the execution time, Greenko partnered with multiple expert logistics firms and both Chennai, Krishnapatnam ports were parallelly utilised to reduce transit time. Close to 4500 numbers of 40’ containers were deployed for transporting the material to the site. More than 4,000 people were mobilised by contractors and a team of 200 Greenko employees was stationed at the site for over 4 months.

High accelerated Construction:

Several dozens of contractors were deployed at the same time carrying out activities such as piling, erecting the module mounting systems, cabling, Setting the modules, building the inverter blocks and the Power evacuation system, and all these activities were efficiently managed by Greenko Project management ably aided by the state-of-the-art real-time progress monitoring software /system built by our own s/w engineers. Average completion rate was 6 MW per day with a peak level of 12 MW. ‘War room’, as the name suggests, was the command centre from real-time decisions were made to ensure that there were no slippages from the schedule. The Pooling substations 2 of 250 MW were completed in 2 months’ time and the construction of 220KV transmission lines kept pace. Close to 5000 km of cabling in about 500 Km of trench, illustrates the mega dimensions of the Project that was built in a record time by Greenko.

Operations & Maintenance:

The Operations & Maintenance of the Ultra Mega solar park is undertaken by Greenko’ s Asset management group. With a staff of about 100 trained AC and DC engineers along with technicians, the Preventive & Breakdown maintenance works are attended to on a daily basis, to maintain high availability of the Plant and the Grid and eliminate under performances, thus leading to high level of Generation and Performance Ratios. Specialised Module cleaning systems are deployed to clean the modules at a fixed frequency so that soiling losses are kept to the bare minimum. High-performance heavy duty vegetation clearing machinery are pressed into service to manage the vegetation growth which otherwise would hinder the operations of the Plant and also become an irritant due to the shadow cast by them on the producing modules. Our teams take care of vendor relationship and efficiently manage warranty administration. Performance sleuths work at the Tech services to identify from the IoT based SCADA system, any under performance of the modules, strings, inverters and resolve them almost within the stipulated time window, through efficient ticketing-based work system. The Operations team ensures that the plant is run optimally taking cognisance of the stipulations and the generation/revenue modelled in the PPA.

‘Safety first’ consciousness:

High standards of Health & Safety are established and compiled through rigorous H&S plan adherence coupled with Risk maps and actual end of period run charts to show critical metric progression. Trained EH&S persons are deployed at the Plant to impart Hazard identification and Risk abatement know how so that the operations & maintenance personnel can drive Safety at all walks. LOTO has been implemented and intensive PTW (Permit to Work) has also been institutionalised.In January 2015 the Indian government expanded its solar plans, targeting US$100 billion in investment and 100 GW of solar capacity (including 40 GW from rooftop solar) by 2022. "With a sweeping commitment to solar power, innovative solutions and energy efficiency initiatives to supply its people with 24x7 electricity by 2030, India is emerging as a front-runner in the global fight against climate change," the World Bank said in a news report published in July 2017. The country added 3 GW of solar capacity in 2015-2016 and over 5 GW in 2016-2017, the highest of any year. Greenko’s 816MWp Ultra Mega Solar Park at Kurnool contributed to this giant leap. Construction of the Plant was started in October 2016 and commissioned on 31st March 2017 – in 166 days, much ahead of the scheduled commissioning date of April 21st, 2017.

500 MW

AC SOLAR CAPACITY

5,932.32

TOTAL AREA

> 1194

UNITS ENERGY

GENERATED ANNUALLY

6 MONTHS

EXECUTION TIME

9,55,000

TONS OF CO2

AVOIDED ANNUALLY

> 4,000

WORKFORCE INVOLVED